Superior performance

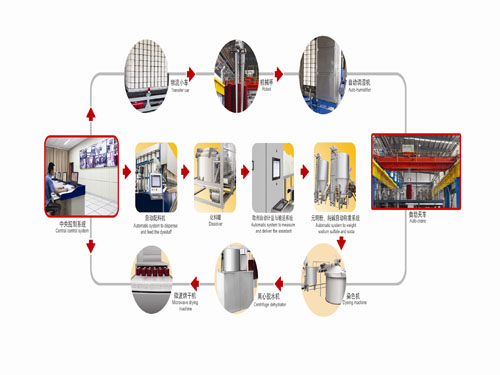

в—ҸDigitization and intelligentize central control system.

в—ҸOnline detecting,hing intelligence and precision control for the dyeing line.

в—ҸIntellige logistics.transfer car and nopower roller with mechanical can match the robot to completethe yarn automatic

shipping and handing between each station.

в—ҸOnline intelligence equipment to regulate humidity of yarn. To overcome the impact of environment change on the moisture-regain of yarn,lower the re-dyeing rate and reduce the repeated consumption of energy and resources.

в—ҸSpecial robot for yarn loading and unloading.Do job such as yarn loading and unloading,yarn pressing,lock installation and un-installation,etc,to liberate labor.

в—ҸAutomatic system to measure and deliver dyestuff and assistant.Precise measurement and assistant,to avoid weighting error and miscarriage by manual.

в—ҸProminent improve one round dyeing FPY and reduce production cost.

в—ҸEliminating the impact of human factor furthest,with significant economic benefits.

в—ҸSmart microwave drying equipment.to achieve faster ,low temperature,high efficiency and even dying.

в—ҸEnery saving and consumption reduced.dyeing machine cylinder with a special coating;heat recovery system;condensed water.cooling wate recovery system;recycle condensation water,coolingwater of about 7 tons,save1.7tons of steam when dye 1ton of yaen.

в—ҸClean precision .For worker,there is no direcr touch on dyestuffs/assistants and exposal to on-site environmental pollution.

в—ҸHigh precision weighing.Weighing tolerance 0.01g,liquid assistant distribute tolerance 0.5%,powder assistant distribute tolerance 0.2kg.

в—ҸThe precision position of logistice system. The positioning tolerance of the transfer car and auto-crane is 5mm,the robot 0.25mm.

в—ҸThrogh the locating device of the sensor to achieve the precision control WSAD

в—ҸUnmanned operation in dyeing workshop.1woeker in central control room can operate the whole production line.

Superior service

в—ҸProvide complete plant for different scale.

в—ҸProvide singe functionality equipment.

в—ҸProvide service of remould and upgrade of the auto-production-line base on existing production.

в—ҸProvide service of remote diagnose on control system,solve the problem

of error effect production in time.

|